Description

Product Introduction

Modular Home Office Residential Container with Flat Pack are sectional prefabricated buildings, or houses, that consist of multiple sections called modules. “Modular” is a method of construction differing from other methods (e.g. “stick-built” and other methods such as off-site construction). The modules are six sided boxes constructed in an exterior (sometimes, remote) facility, then delivered to their intended site of use. Using a crane, the modules are set onto the building’s foundation and joined together to make a single building. The modules can be placed side-by-side, end-to-end, or stacked, allowing a wide variety of configurations and styles in the building layout.

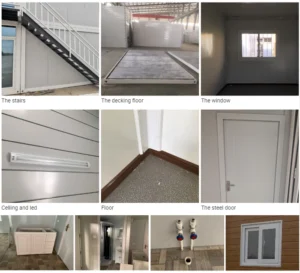

Standard Flat Pack container house : can be easily installed; broken bridge aluminum doors and windows; high-grade metal ceiling; SPC high strength composite floor; blue board bottom with waterproof and moisture-proof features.

Simple Flat Pack container house with high cost-effective.

Modular Prefabricated buildings, also called prefabricated buildings, differ from mobile homes, which are also called manufactured homes, in two ways. First, modular prefabricated building/homes do not have axles or a frame, meaning that they are typically transported to their site by means of flat-bed trucks. Secondly, modular prefabricated buildings must conform to all local building codes for their proposed use, while mobile homes, made in the United States, are required to conform to federal codes governed by HUD (U.S. Department of Housing and Urban Development).[1] There are some residential modular prefabricated buildings that are built on a steel frame (referred to as on-frame modular) that do meet local building codes and are considered modular homes, rather than mobile homes.

Product Parameters

| Internal Size | 5800x2150x2890mm / 5800×2380*2890mm |

| Standard Configuration | 1 open room with 1 door, 2 window and electrical system |

| Steel Frame: Roof | galvanized roof beam 3mm thickness,galvanized sub-beam C90, 2mm thickness |

| Steel Frame: Floor | galvanized floor beam 3.5mm thickness, galvanized sub beam steel square tube 1.8mm thick |

| Wall | 50/70mm EPS sandwich panel, glassfiber sandwich panel, or PU sandwich panel |

| Door | steel door |

| Window | UPVC window frame, sliding window |

| Electrical | socket, switches, lights, electric wire, brake |

Product Details

Flat Pack Container Installation Steps:

1. Placethe base, it is in a horizontal state

2. Installthe corner column, fixed on the base

3. Installationof the base, fixed with bolts

4. Thecorner column and the base vertically tightening bolts.

5. installationdownpipe in corner column.

6. Installouter wall panel and doors and windows.

7. Thepress plate and the chute are fixed , as the bolt is tighteded.

8. Crownmoulding buckled on the plate, sealant is used in the included angle to make itclose.

About

Specilaze in steel structure for around 20 years

100% Tested before sale

Cooperate with over 35 famous brands from domestic and international market

Competitive and reasonable price

Abundant inventory and short lead time about 35 work days

10 Year warranty

24hrs supports from our sales and R&D team

Competitive and reasonable price

Our services

1.Oem or odm are acceptable.

2.We accept small order/trial order for customer to check whether the products is suitable for the market.

3.Will be available online almot in 24 hours service for your esteemed company.

4.We are glad to hear from you soon and to start a business relationship with your esteem company.

If you have another questions,please feel free to contact us.

Reviews

There are no reviews yet.