You need to focus on maximum output and efficiency while being committed to hygiene and safety, this is what will guarantee a successful bottled water production.

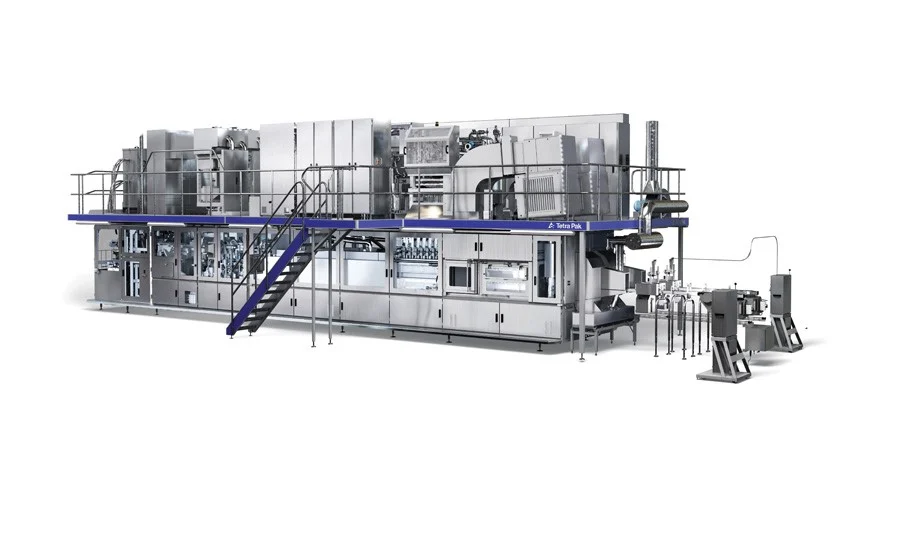

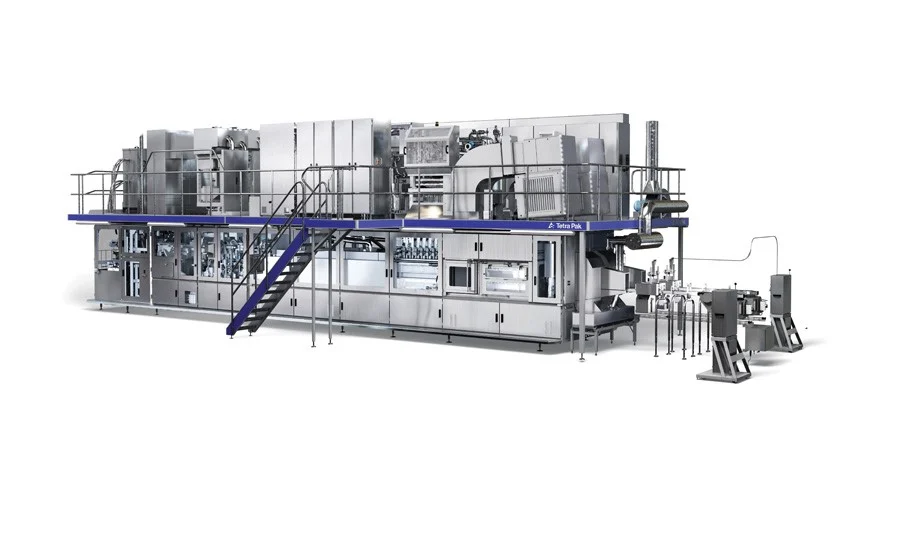

Also, when you purchase your bottled water production machine from manufacturers who are reputable for good quality, your entire bottled water production line will be very efficient. Obviously, this will help save your time, energy, and money.

In preparation for a successful venture, let’s see what you should consider before taking the dive into a bottled water production line.

1. Evaluate available space before purchasing equipment

The available space you have for your production line determines the type of machines you would be purchasing.

For this, large machines with large conveyors are simply not good choices for smaller spaces.

Lack of space can be a limitation, but tabletop, semi-automatic, or customary machinery could be adapted to fit their intended purpose.

Analyzing your landmass will ensure efficiency and maximum productivity in your chosen venture.

2. Products analysis

It is imperative to analyze different packaging formats of your water since the processes of different water production lines vary.

Also, analyzing the look of your final products will also help you determine the features necessary for the best performance of your machine.

3. Decide the number of bottles to be produced per time.

The demands of the business will determine the speed of production. It is therefore good to have a projection of the number of bottles per minute you wish to produce, based on the set daily demands.

For instance, if a company must produce 5000 bottles over an 8-hour period per day, it will be required to reach about 10 bottles per minute.

Putting these numbers into consideration will help you to purchase a bottled water production line and the mechanization level that will help you to achieve the set goals.

4. Consider future progress/expansion

To ensure that your water production line does not become quickly worn out by the demand for production, it is important to evaluate your future growth.

The current level of production and demand can project what is to come in the nearest future. By this, you can speculate growth and plan for it and create room for upgrades.

Planning for your growth will save you the expense of packing off existing lines and purchasing new ones at such short intervals.

5. Put your choice of containers into consideration

The shape and sizes of your containers may usually not affect the method of filling water into the bottles or the machine used.

However, a good knowledge of container sizes will definitely help with your bottled water production line design.

Also, your design should be able to adapt to specifications such as dives and heights of the bottles that you intend to use.

When you choose your containers, parts such as the fillers, corks, neck grabbers will be hand-tailored to your peculiar needs and this will ensure optimum performance of your bottled water production line.

Conclusion

Setting up a bottled water production line is a venture with enormous ROI, especially when due consideration is given to all that is required for a smooth operation.

Besides putting all the factors above into consideration, purchasing your machines and equipment from a trusted manufacturer is a sure way to invest your money in the right venture.